How to Best Support Digital Twins

Michael Stonebraker

December 20, 2022

In this blog, post we first review the definition of a digital twin. Then we argue that a detail-on-demand visualization system should be an integral part of the software system used for gaining insight from digital twins.

I Introduction

A digital twin is defined by Wikipedia as:

A digital twin is a digital representation of an intended or actual real-world physical product, system, or process (a physical twin) that serves as the effectively indistinguishable digital counterpart of it for practical purposes, such as simulation, integration, testing, monitoring, and maintenance.

The concept is popular in a factory floor setting, where a client would construct a physical model of the factory. Then, he could use the model to visualize the state of the factory floor where alerts and state variables could be displayed. And, if he wanted to try alternative scheduling, configuration, or state variables, he could run a simulation on the model to see alternate results. Testing is another excellent application.

There are many other environments beyond factories where a digital twin could be useful. In a building, for example, one could look at alternate heating strategies. In an urban road network, a digital twin would be useful for exploring alternate settings for traffic lights. And, one could use a digital twin for exploring alternate air traffic control strategies for a busy airport. In this blog post, we will use a factory floor as an exemplar.

II Requirements for a Digital Twin

In this section we list four requirements that display software for digital twin applications should satisfy.

Requirement 1: Display of information on the screen using a 2-D or 3-D spatial model.

A digital twin is inevitably spatial in nature. Hence, the screen should be able to render the model either in 2-D (flat world) or in 3-D (reality). Of course, 3-D is much more expensive computationally than 2-D, so I expect products will offer compromises having some of the features of 3-D, but much less expensive computation. Obviously, one must be able to decorate the spatial model with user information. That comes from monitoring or simulation software. For example AirBnB decorates a Google map with locations of available properties.

Requirement 2: The ability to pan

A large digital twin will not fit on the screen in its entirety. Rather, the ability to pan around a bigger model, with relevant spatial information being rendered on the screen is needed. Otherwise, one will not have the ability to scale digital twins to large sizes.

Requirement 3: The ability to zoom

I claim a digital twin is inevitably hierarchical. For example, a component of a machine could have a digital twin. A group of components make up the machine and could have a digital twin. In a factory, there are many machines, representing the next level of a hierarchy. Finally, there can be many factories in a company’s portfolio. As a result, a natural hierarchy would be:

Enterprise

|

Factory

|

Machine

|

Component

The simplest application of a digital twin is for monitoring. In this case a traditional dashboard would present summary data on the state of the enterprise. Figure 1 shows an example dashboard from a real application in Brazil, where the tags are in Portuguese.

However, much information is lost in this presentation. For example, if there was a power surge or outage in a small area, that information is not available in Figure 1. In other words, Figure 1 loses context.

However, much information is lost in this presentation. For example, if there was a power surge or outage in a small area, that information is not available in Figure 1. In other words, Figure 1 loses context.

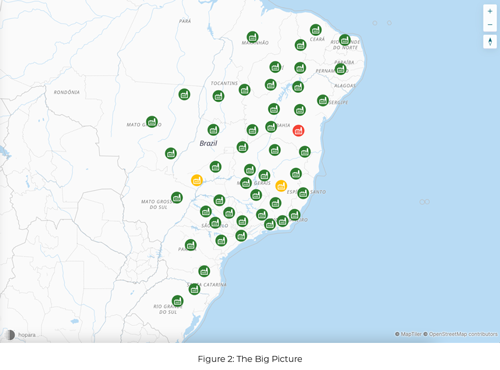

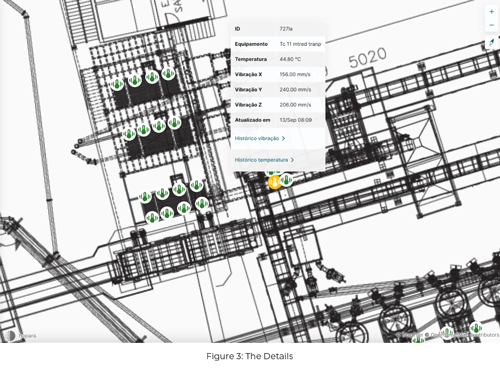

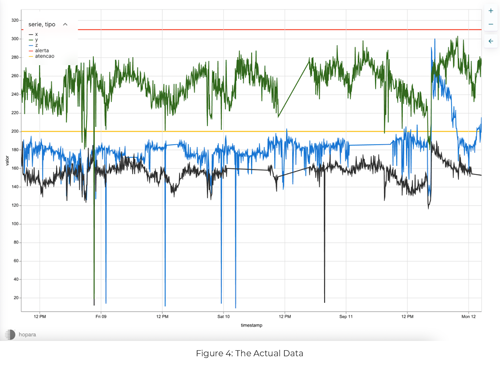

Instead, the enterprise with this application wanted the display in Figure 1 augmented with the information shown in Figures 2-4. Here, he starts with an overview of the 58 factories in his enterprise. In this display he can quickly see the overall health of his factories. In fact, there are three with significant issues, and he can drill-down to get specific information. Further detail can be obtained on the red factory in Figure 3 with another click. Finally, Figure 4 shows the voltage waveform over time of this factory, and we notice a spike that probably caused the issues in this factory.

Notice in Figures 2-4 the display is a map (Figure 2), a floor plan (Figure 3) and a time series plot (Figure 4). A crucial requirement is:

Requirement 4: The ability to render multiple kinds of data onto the screen

I claim that these four requirements are the minimum required to support digital twins. There may well be other requirement, such as the ability to support real-time changes to the display. Moreover, it goes without saying that response time to user gestures must be less than 0.5 seconds, or real users will get very frustrated.

Supporting all four requirements is crucial to success, and Hopara is the only commercial product that I know of that supports all four requirements.