Hopara and Elemental Machines

Enhance asset utilization and better predict and prevent downtime

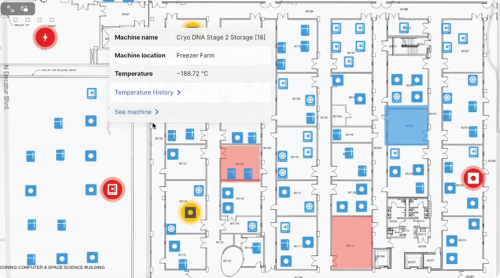

The partnership between Hopara and Elemental Machines (EM) enables customers to enhance asset utilization and better predict and prevent downtime by monitoring and visualizing all their lab devices via an interactive floorplan.

In the age of Industry 4.0, companies are amassing vast amounts of data, particularly through IoT sensors, and traditional tools are struggling to handle the volume and complexity of data. An excellent solution to this problem is a Hopara Agile Digital Twin, which acts like a virtual sentinel, watching over lab operations in real-time. With this digital twin solution, organizations can efficiently visualize their data in the context of a floor plan in a manner akin to Google Maps, while also connecting to multiple real-time databases and enhancing user experience to boost data utilization in daily tasks.

Hopara seamlessly leverages real-time operating data from Elemental Machine’s IoT sensors, which connect virtually to any lab equipment, from any brand, with any function, from any era. Elemental Machine’s plugand-play sensors begin transmitting data 60 seconds after unboxing. The Hopara/EM solution delivers insights within an engaging and user-friendly environment at a fraction of the time and cost typically associated with full-scale digital twins.

The combination of Hopara and EM software allows users to see real-time alerts, status, and availability of all equipment in context. Furthermore, with the ability to drill down for more detail on-demand, Hopara’s visualization layer users will benefit by:

Interacting with facilities in a totally new way

- Navigate swiftly from the highest level of abstraction, such as individual labs or floors to more granular details of a specific instrument with advanced drill-down

- Speed and simplify the implementation process with a low-code approach

- Get even more value from the Elemental Machines Platform

Monitor and troubleshoot devices

One Lab Manager described the Hopara Agile Digital Twin solution as “crazy fantastic.” He gets alerts in the middle of the night but has to sift through lists to identify what and where the problem is. He wants to see where the device is immediately and understand the issue quickly. Now, the ability to see his devices in the context of a lab floorplan with the ability to drill down for more information (such as “What is the current temperature?” or “When was it last above the temperature threshold?”) offers him the ability to rapidly troubleshoot and solve problems. And most importantly, he gets back to sleep far more quickly with vastly less stress.

Predict and prevent downtime

With Hopara digital twins seamlessly integrated with EM’s IoT-enabled equipment monitoring, customers capture real-time data on equipment status and performance, while also gaining an enhanced understanding of usage patterns and trends. This integration not only allows users to filter and identify devices in need of regular maintenance, but also connects historical data to physical assets enabling precise predictive maintenance, troubleshooting, and optimization. By leveraging this comprehensive approach, labs can proactively prevent unplanned downtime, reduce costs, and enhance reliability while continually improving operations based on equipment-specific trends and patterns.

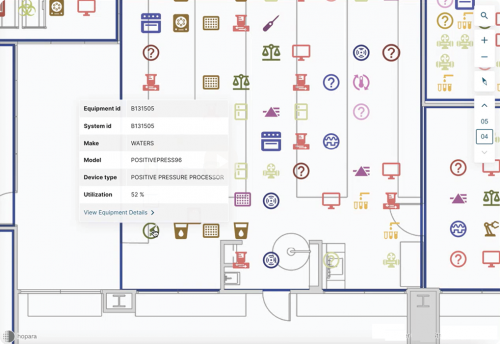

Enhance asset utilization

The instant visibility into instrument status, condition, and location made possible by the combination of EM’s equipment monitoring and Hopara’s digital twin solution offers unique real-time insights that help improve asset utilization. The visually appealing presentation focuses on relevant information, advanced drill-down allows for easy data navigation, and identification of equipment- and location-based trends and patterns helps reduce costs by enabling more efficient asset utilization and improved scheduling.

Empower scientists with better data

Science often involves complex protocols requiring a plethora of equipment. In many cases, finding the right instruments and supplies is a challenge. But this is no longer the case with the combined power of EM and Hopara. Now, scientists and lab professionals can proceed with ease. This efficiency is driven by the ability to quickly locate and identify available equipment, and reserve it if needed.

With the combination of extremely rich detailed sensor data from Elemental Machines and the easiest way on the planet to visualize the EM data in the context of a lab floorplan from Hopara, customers can more easily get the desired insights for purposes such as planning, monitoring, scheduling, and troubleshooting. With data collection from EM and interactive visualization and actionable insights via Hopara, customers get the best of all worlds.