- Case Study

Latin American E-Commerce Leader – Warehouse Belt Monitoring

About the Client

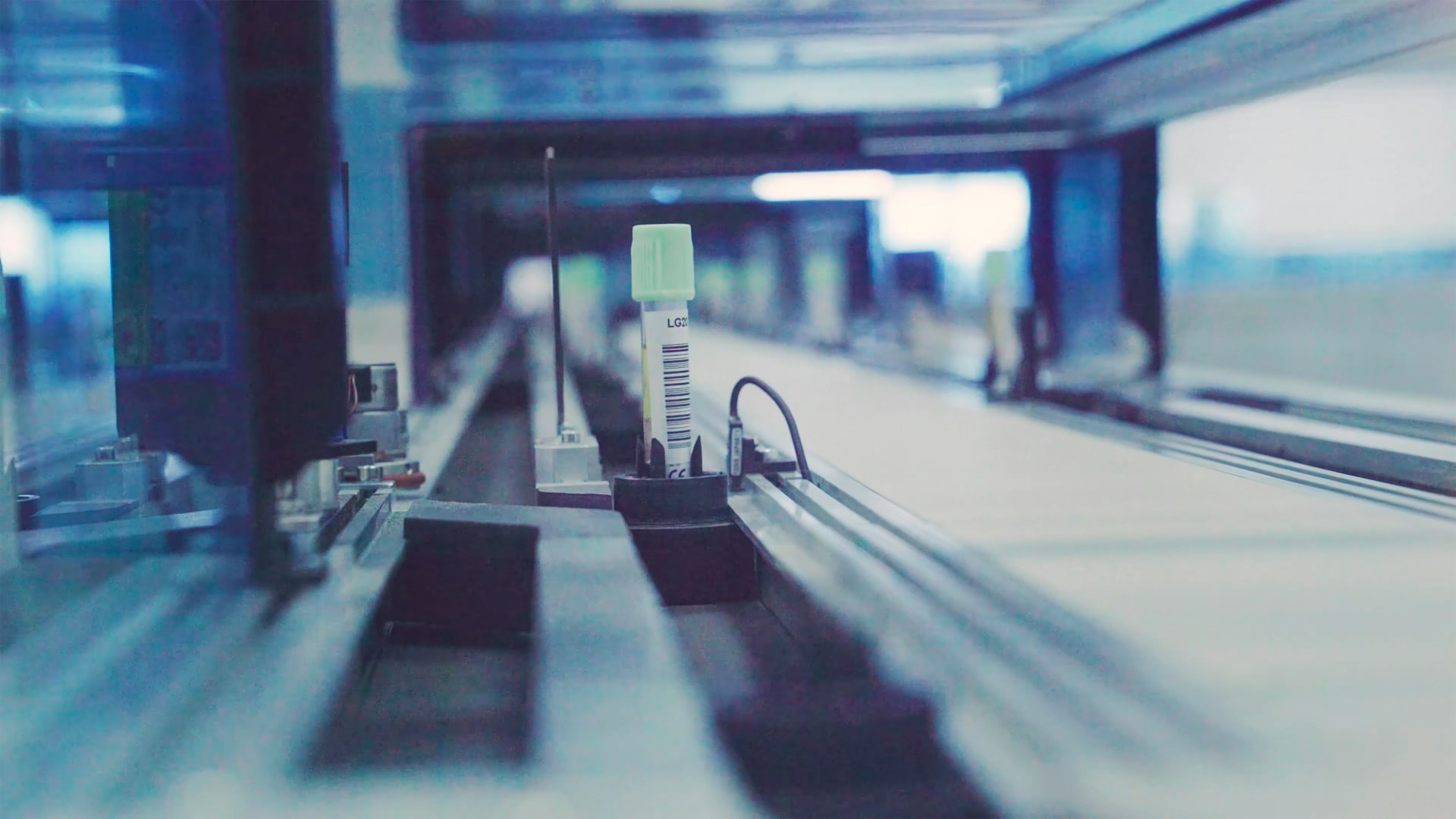

One of Latin America’s largest e-commerce platforms operates a massive logistics network in Brazil, with 17 distribution centers spread across the state of São Paulo. These sites are strategically positioned to serve high-volume demand, but are separated by large distances, some as far as 500 kilometers apart. Each facility processes thousands of packages per hour, relying on continuous conveyor belt operations to meet tight delivery windows.

Problem

The conveyor belt system is a mission-critical component in the company’s fulfillment process. Any malfunction, especially emergency stops can immediately create bottlenecks, delay shipments, and increase operational costs.

- Visibility challenge: The central operations team lacked a unified way to monitor the health and status of conveyor belts across all sites.

- Slow incident response: When a belt stopped unexpectedly, local teams had to manually report issues, creating delays in troubleshooting.

- Operational risk: With high throughput and seasonal peaks, even a few minutes of downtime per site could ripple across the network, leading to missed delivery commitments.

Solution

Hopara implemented a visualization that provides a live operational map of all 17 distribution centers.

- Multi-scale monitoring: From a regional view, users see real-time operational status indicators for each site.

- Facility-level detail: Drilling down into a site reveals a 2.5D representation of the warehouse layout, with each conveyor belt system shown in its physical position.

- Real-time alerts: Emergency stop events are instantly highlighted on the dashboard

- Motor health tracking: The system integrates sensor data, allowing operators to monitor motor temperature, vibration, and runtime, helping predict maintenance needs before failures occur.

Result

The visualization platform transformed the company’s ability to maintain uptime across its distributed network.

- Reduced response time: Emergency stop incidents are now detected and escalated within seconds.

- Lower downtime: Faster troubleshooting and coordinated remote support have reduced conveyor belt downtime.

- Improved throughput: With fewer disruptions, the company maintained stable throughput even during seasonal spikes.